PTFE Spring Energized Piston Seals

PTFE Spring Energized Piston Seals are innovative seals that are designed to deliver optimal performance in a wide range of industrial applications. They are made from a variety of materials, including PTFE (polytetrafluoroethylene), stainless steel, and carbon, and are designed to withstand extreme temperatures, high pressures, and corrosive chemicals.

Designed to suit a variety of engineering applications, these seals are highly reliable and durable, and can be custom designed to meet specific customer requirements.

Function:

PTFE Spring Energized Piston Seals are designed to provide a leak-free, pressure-tight seal that can withstand high-pressure environments. They work by using a spring that is compressed against the seal lip, which creates tension and compresses the seal material against the piston or cylinder. The spring then pushes the seal against the surface to prevent any leakage.

The PTFE material used in the manufacture of these seals facilitates their durability, resistance, and ability to withstand harsh environmental conditions. These properties are essential in achieving a long-lasting, high-performing seal.

Advantages:

1. Resistance to High Temperatures: PTFE Spring Energized Piston Seals can withstand extremely high temperatures and can operate in both hot and cold environments.

2. Resistance to Corrosive Chemicals: These seals can withstand corrosive chemicals such as acids, bases, and solvents, making them ideal for use in chemical processing plants.

3. High Pressure Resistance: These seals are designed to withstand high pressure and can provide exceptional seal performance under extreme pressure.

4. High Durability: PTFE Spring Energized Piston Seals are built to last, offering high levels of durability, longevity, and reliable performance.

5. Versatility: These seals are suitable for a range of applications, including hydraulic and pneumatic systems, pumps, valves, and compressors.

Applications:

1. Chemical Processing Plants: These seals are used to seal chemical reactors, pumps, valves, and other equipment used in chemical processing plants.

2. Aerospace: PTFE Spring Energized Piston Seals are used in aircraft hydraulic systems, actuators, and other equipment that undergoes high stress and demanding environmental conditions.

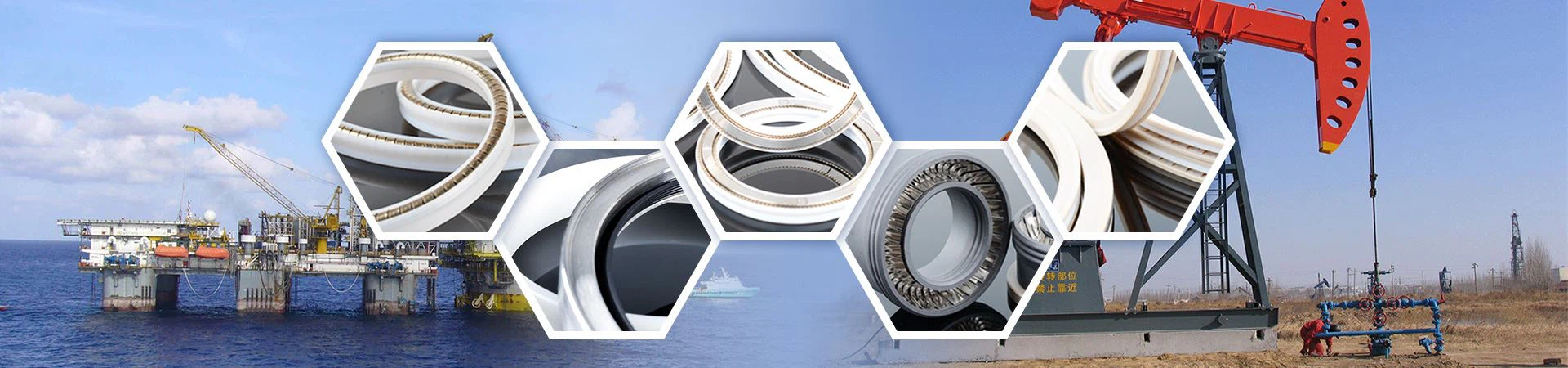

3. Oil and Gas: These seals are ideal for use in oil rigs, drilling equipment, pipelines, and other equipment that handle high pressure and corrosive materials.

4. Medical Technology: PTFE Spring Energized Piston Seals find use in medical equipment such as surgical robots, imaging equipment, and prosthetics.

5. Other Applications: These seals can also be used in various other applications such as food processing, and automotive engineering.

Conclusion:

PTFE Spring Energized Piston Seals are an excellent sealing solution that delivers high-performance, durability, and reliability. They are suitable for use in various industrial and engineering sectors and are rapidly gaining popularity due to their efficient sealing capabilities and versatile applications. With custom design options, it is possible to choose seals that meet specific requirements, making them an excellent investment that offers long-lasting performance and reliability.

Hot Tags: ptfe spring energized piston seals, manufacturers, suppliers, factory, customized, PTFE Lip Seal, 40MPA UHMW PE Energized Spring Seal, F222 40 Bronze MoS2 Filled PTFE, RPTFE Stem Seals, EPDM 85 Shore Black, FPM 85 Shore FDA Brown

Products

Products

Spring Energized Seal

Spring Energized Seal