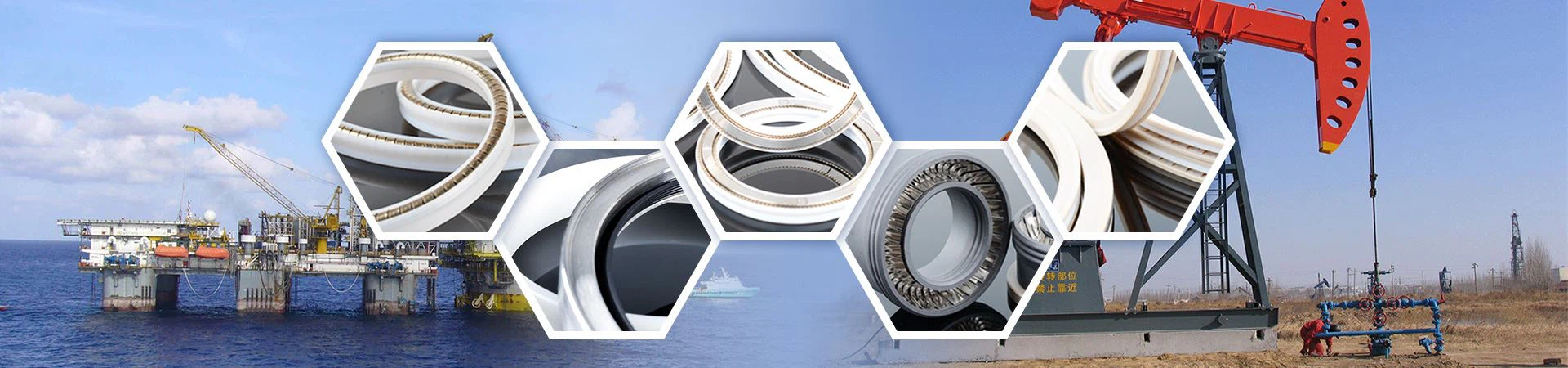

Helicoil Spring Energized Seal

Product Introduction

This helical shape spring affords a relatively high load versus deflection range resulting in a seal product that can provide very tight sealing.

Best applications for Helical Spring Seals.

Kaflon supply 300 Series stainless steel, Elgiloy, Hastelloy 276,etc.

Product Parameter (specification)

Helical Spring Seals are comprised of a wound ribbon metal spring installed in a polymer jacket. This helical shape spring affords a relatively high load versus deflection range resulting in a seal product that can provide very tight sealing. As a highly loaded product, Helical Spring Seals should be considered when dynamics are very slow or static. Examples are in stems seals and in cryogenic valves where additional force is required to overcome thermal effects.

Product Details

As a highly-loaded product, Helical Spring Seals should be considered when dynamics are very slow or static.

Examples are in stems seals and in cryogenic valves where additional force is required to overcome thermal effects.

Spring-energized PTFE Seals are suitable for service in the following industries:

Pharmaceuticals Liquid Chromatography

Food Processing Space Exploration

Tire Production Hydraulics

Vacuum Service Oilfield Exploration and Production

Paint and Solvents Steel Mills

Adhesives Cryogenic Service

Liquid Handling Swivels Pumps and Valves

Gas Production and Transportation

Medical Equipment Gas Handling Equipment

Our company

Kaflon is located in No. 75 Tian An Road, Jimei District, Xiamen City, Fujian Province.

Kaflon has ISO9001, API certificate,etc

Kaflon services oil&gas, LNG ball valve, Downhole tool

Kaflon cooperated with LNG project in domestiv and foreign projects,like Middle East Petroleum project

The application of Kalfon's products covers

Kaflon Seal apply in the industry of petroleum, petrochemical, natural gas, steam system, electric power, metallurgy, shipbuilding, food environmental protection, sewage treatment, papermaking, etc., In the chemical and petroleum and natural gas complete equipment, seals for valves Applications are especially critical.

Our Advantages

* Each of our service personnel is a professional sealing technical engineer.

* The raw materials we use are all international first-line brands.

*We offer sealing products in the most demanding sealing environments

* We provide product emergency services, and customers order and mold on the same day.

* We accept small orders, O-rings do not charge molds.

FAQ

Q1: What is the normal lead time for product orders?

A: Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10 days, average production time after sample approval is 2-3 weeks.

Q2: What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

Q3: How to select the raw compound for my application?

A: With years of experience working with a variety of material, we can help select the material that will best suit your needs while keeping material costs in mind.

Hot Tags: helicoil spring energized seal, manufacturers, suppliers, factory, customized, Spring Energized Seal, Canted Coil Spring Energized Seal, Helicoil Spring Energized Seal, Cantilever Springs Spring Energized Seal

Products

Products

Spring Energized Seal

Spring Energized Seal